Types of motion

- Linear - movement in a straight line - i.e. a train

- Rotational - movement in a circle - i.e. the wheels of the train

- Reciprocating - back and forth movement in a straight line - i.e. a pneumatic drill

- Oscillating - back and forth movement along an arc - i.e. a pendulum

Levers

Levers use distance to magnify force. The further away from the pivot the force is applied, the more it is magnified, therefore levers can be used to lift heavy loads with smaller forces.

So, in this example, the force we are trying to lift is 30N, it is magnified by 5 (5cm away from the pivot) the input force we need to put in is magnified by 15cm, therefore we have to apply an input force of 10N.

Pulleys

Pulleys are another mechanism used to magnify a force by a distance to make something easier to lift. By increasing the distance of rope pulled through the mechanism less force can be used. This only works with more than one pulley.

The mechanical advantage is a way of describing how much easier the load is to move with the pulley. You can work out the mechanical advantage by using the equation:

load

MA = Effort

The velocity ratio concerns the distances covered by both the load and the effort. You can work out the velocity ratio by using the equation:

distance moved by load

VR = distance moved by effort

You could also count the ropes (not including effort) to find the velocity ratio.

No mechanical system is 100% efficient due to friction in the moving parts, so you will need to put in more force in real life than in calculation to move the load. The efficiency can be calculated using the equation:

Mechanical Advantage

Efficiency = Velocity Ratio

Rotary Mechanisms

All rotary mechanisms are used to increase or decrease speed, and/or change the rotation through different angels (most commonly 90)

You need to know about:

- Spur Gears (Gear trains plus using an idler)

- Chain and Sprocket

- Belt and Pully

- Worm and Wheel

- Face Gears

- Bevel Edge Gears

The velocity ratio of all rotary systems can be found using the generic equation:

the amount of input motion

VR = the amount of output motion

However we can use simpler equations when we know the size/number of teeth on a gear. This can apply to chain and sprocket, meashed gears, bevel edged gears and face gears. If you want to find the Velocity Ratio of a belt and pulley, you can follow the same theory but you will have to use the diameter of the pulley as it will have no teeth.

A smaller gear will always turn faster, therefore is a small gear is driving a bigger gear you will get a speed reduction so you are looking for the Velocity Ratio to be a fraction.

So if gear A is the driver, and gear B is the driven, you can find the VR = A/B = 12/18 or simplified to 2/3. So if gear A turned at 300 rev/min, gear B would turn at 2/3 of that speed = 200 rev/min.

If a larger gear is driving a smaller gear you will have an increase in speed and are therefore looking for a whole number as your velocity ratio. So if gear B was the driver and gear A the driven the VR = B/A = 18/12 = 1.5. So if gear B turned at 300 rev/min, gear A would turn at 1.5 x 300 = 450 rev/min.

When deciding between a chain and sprocket and a toothed belt you need to consider the function of the mechanism. A chain and sprocket is very good for eliminating slip, but if something jams in the mechanism and a motor is being used as your input, the motor will be trying to turn but can't so will burn out, a belt would allow the motor to still turn as it would slip over the pulleys and so the motor is protected. Something with manual input like a bike is very suited to a chain drive to ensure that every rotation of the pedals results in a turn of the wheel.

You can try to increase friction between the belt and the pulley by changing the type of belt to a V-belt or a toothed belt.

To make sure that the belt does not stretch so that it falls off the pulley, a tensioner or jockey wheel may have to be used.

Worm and Wheel

A worm and wheel is a special rotary system as it only allows rotation in one direction - i.e. the worm can only ever be the driver so acts as a brake. The worm and wheel also produces a big reduction in speed as the worm only has one tooth. So VR = 1/number of teeth on worm.

Bevel Edge Gears

Bevel edge gears often do not have a difference in size as their main purpose is to transmit the rotation through 90.

Face Gears

Face gears transmit rotation through 90 and can also have a velocity ratio by changing the size of the gears used.

Compound Gear Systems

Compound gear systems combine mechanisms to produce a greater velocity ratio. This is done by adding two gears on the same axle. As these must be turning at the same speed, there is no velocity ratio between them, but now the driver of the second "pair" is turning at the same speed as the driven of the first "pair."

The above picture and graph shows a motor turning at 120 rev/min. There is a great reduction in speed with the worm and wheel - VR = 1/10 (the blue line shows the speed of the wheel) a further reduction with the first chain drive - VR = 10/20 (the green line) and a last reduction with the second chain drive - VR = 15/25 (the purple line).

So we can work out the total VR:

VR = 1/10 x 10/20 x 15/25

=

0.03

The output speed will be the motor speed x VR so:

Output speed = 120 x 0.03

=

3.6 rev/min

If an idler mechanism was used, the effect of the speed reduction would be greatly reduced as the idler does not affect the velocity ratio, only the driven and the driver.

Rotary to Linear

The rack and pinion turns the rotary motion of the pinion into the linear motion of the rack. You can do calculations based on the number of teeth per metre on the rack and the speed of the rack.

i.e. if the rack has 100 teeth per metre and the pinion has 10 teeth, it has to turn at 10 revolutions a second for the rack to move 1m/s.

Rotary to Reciprocating

Crank and Slider: A crank is motion off centre of a circle. This could be a single member, or a wheel. The off centre motion pushes the slider back and forth, thus creating reciprocating motion.

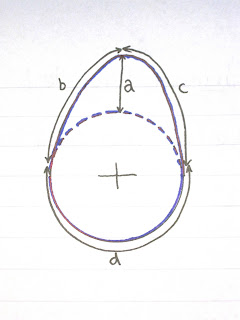

Cam and Follower: The raised section of a Cam pushes a follower up and the dewll makes it fall again. There are many shapes of Cam, the most common of these being a pear shaped cam.

Click here for more information about cam and follower

Safety Mechanisms

Sometimes it is necessary to ensure rotation in one direction only. As mentioned before, a worm and wheel could be used for this purpose. Alternatively a Ratchet and Pawl could be used. This works by shaping the teeth on the ratchet so that in one direction the pawl slides over them and in the other direction gets stuck, stopping the mechnism.